845 401.3880

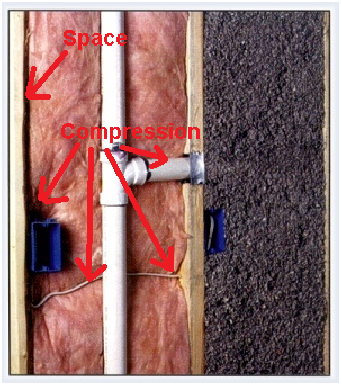

Detail shows space space on left hand side of the insulation and all around the electrical box.

Detail shows space space on left hand side of the insulation and all around the electrical box.

There are several areas of insulation compression like around the PVC pipe, electrical wire and the electrical blue box.

A Very Smart Choice

Cellulose insulation is a smart alternative to fiberglass because it provides a green, efficient, non-

The common standard by which insulation is measured, R-

A little history

Cellulose insulation has been around for a long time. Thomas Jefferson used some form of cellulose to insulate his Monticello home estate in Charlottesville VA, at was in 1769! What we think today as cellulose insulation has been in wide use since the 1920's, growing dramatically after WWII. The energy crisis of the 1970's led to an even greater use of cellulose because of greater improvement in quality and sophistication, now providing exceptional resistance to fire, moisture, mold, and vermin; but that dramatically changed once the big box stores started to offer fiberglass insulation batts to homeowners with a tempting low price and a high promise of big energy savings and the half true fact that fiberglass insulation is much easier to install that cellulose –but that is because not many people knows the real secret about how fiberglass really works and the truth complications involved on its proper installation. So the ubiquitous bales of pink and yellow fiberglass currently insulates more than 90% of the new homes built in the United States even though building scientists, engineers, and home performance contractors have realized for a long time now that this pink and yellow bales are really not the best insulators and cellulose insulation passes as a strong contender.

that cellulose –but that is because not many people knows the real secret about how fiberglass really works and the truth complications involved on its proper installation. So the ubiquitous bales of pink and yellow fiberglass currently insulates more than 90% of the new homes built in the United States even though building scientists, engineers, and home performance contractors have realized for a long time now that this pink and yellow bales are really not the best insulators and cellulose insulation passes as a strong contender.

The truth about fiberglass insulation

The insulation properties of fiberglass is not from the glass fibers it is made, but from the tiny millions of air bubbles contained in the insulation –the more air bubbles, the largest R value it has. So heat, a form of energy, passes through the glass fibers quickly because of conduction, since air has such a low thermal conductivity, heat slows way down when it gets into the air bubble, and that process repeats itself millions of times until the end of the insulation material In contrast to fiberglass insulation, cellulose insulation does not slows heat from air bubbles in between it is its fibers that slows the lost of heat. Cellulose origins are from wood fiber and the cellular structure of wood is naturally more resistant to the conduction of heat, which means cellulose insulation can be compressed into a space and offer additional r-

1) Many people think that pushing more fiberglass in a cavity to get more fiberglass would increase the R value of the space, while in reality, the truth is the opposite, reducing the air bubbles increases the conductivity properties of the fiberglass, increasing the speed at which the heat passes through.

2) Walls, ceilings, and floors of your home are full of odd shaped cavities and obstacles like plumbing, air ducts, electrical wiring and electric boxes. For fiberglass to work effectively to the stated R value, it must completely uncompressed fill around all these obstructions without gaps or voids. Any gaps and voids can reduce the actual performance of batts can be 14% to 45% less than their labeled R-

3) Due to air circulation and natural convection, the R-

Calculations showed that cellulose tightened the building 36% to 38% more than fiberglass.

An overnight heat loss test revealed that after nine hours (midnight to 9 a.m.), the cellulose-

Most significantly, after three weeks of monitoring the cellulose-

Their final conclusion was that cellulose performs as much as 38% better than fiberglass in extreme weather. The performance advantage of cellulose in temperate climates appears to be about 26%, and the report projects that "this benefit would become more significant in more severe climates."

It is a good option for environmentally conscious consumers because Cellulose is “green.” Would it surprise you to learn that cellulose is the most common building material in the world? It should not because wood is the base of paper and cardboards, which then becomes cellulose, so you might be tempted to think of cellulose insulation as paper, or even ground-

Cellulose insulation is safe. It is made of paper, and chemically treated to provide permanent fire resistance -

Walls are fully and tightly insulated, forming a monolithic thermal barrier with no more gaps. No more voids, no more drafts, just years of comfort because cellulose will not lose its energy saving abilities over time.

Gaia Sharbel Energy © A Green Company. Complete Energy Solutions for your home or office

Cellulose of tranquility